Custom Fiberglass Cartoon Figure Sculpture

1.How about the installation?

We provide installation instructions

A.The small product contains all the parts needed for installation. Just follow the instructions and connect them

B.We provide on-site installation service for large products. The product price includes personnel costs,Guests can only provide air tickets and accommodation

2.What about the after service?

A.Two years of after-sales service.

B .Provide lifelong technical service

3.can you provide personalized and customized product?

A.Of course, the customer provides the design and requirements. We will make a detailed production plan and confirm with the customer.

B.If the customer cannot provide the finished design, they can also provide the preliminary idea of the product or scene they want to do. We provide the reference opinion and the production plan to help the customer achieve the expectation.

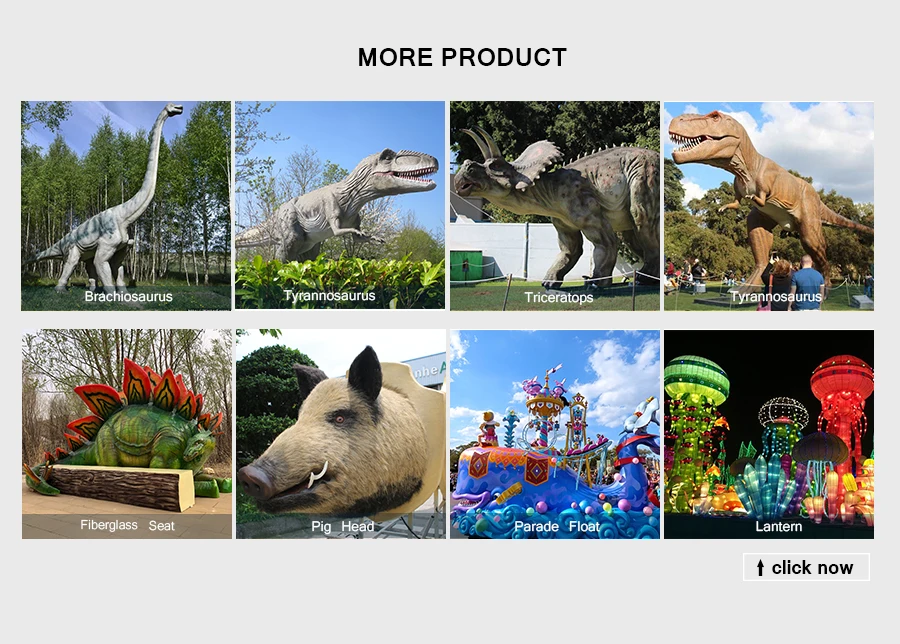

We can provide customized service in mechanical structure, control mode, special effect, material texture, function.Such as stage props, activity props, performance special effects costumes, parade floats, scene special effects.

4.How long is the duration of the production?

A.Regular products, such as dinosaurs, animals, insects, Marine life, have A production cycle of 30 to 60 days,It’s different for depending on the amount.

B.Customized products need to consult with the salesman

5.why choose us?

A.we have our own production factory and 9 years of large project production experience

B.Stable and perfect company platform, strict quality and process management (OA & QCS)

C.Own r&d team (control system, mechanic, New material), and provide pre-sales technical support.

D.Provide product and scene plane and 3D design services

E. Multilingual service, barrier-free communication

F.24 hours Response to after-sales service

outdoor children playground equipment fiberglass theme park decoration fiberglass decoration sculptures playground decoration outdoor fiberglass cartoon lifelike animal model fiberglass animal decoration outdoor animal fiberglass cartoon fiberglass animal suppliers halloween theme park decoration outdoor animal statue waterproof outdoor fiberglass animal model

Cartoon fiberglass fiberglass sculpture

Fiberglass (American English), or fibreglass (Commonwealth English) is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet (called a chopped strand mat), or woven into glass cloth. The plastic matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinyl ester resin—or a thermoplastic.

Cheaper and more flexible than carbon fiber, it is stronger than many metals by weight, is non-magnetic, non-conductive, transparent to electromagnetic radiation, can be molded into complex shapes, and is chemically inert under many circumstances. Applications include aircraft, boats, automobiles, bath tubs and enclosures, swimming pools, hot tubs, septic tanks, water tanks, roofing, pipes, cladding, orthopedic casts, surfboards, and external door skins.

Other common names for fiberglass are glass-reinforced plastic (GRP), glass-fiber reinforced plastic (GFRP) or GFK (from German: Glasfaserverst?rkter Kunststoff). Because glass fiber itself is sometimes referred to as "fiberglass", the composite is also called fiberglass-reinforced plastic (FRP). This article will adopt the convention that "fiberglass" refers to the complete fiber-reinforced composite material, rather than only to the glass fiber within it.

The fiberglass mold process begins with an object known as the plug or buck. This is an exact representation of the object to be made. The plug can be made from a variety of materials, usually certain types of foam.

After the plug has been formed, it is sprayed with a mold release agent. The release agent will allow the mold to be separated from the plug once it is finished. The mold release agent is a special wax, and/or PVA (Polyvinyl alcohol). Polyvinyl alcohol, however, is said to have negative effects on the final mold's surface finish.

Once the plug has its release agent applied, gelcoat is applied with a roller, brush or specially-designed spray gun. The gelcoat is pigmented resin, and gives the mold surface a harder, more durable finish.

Once the release agent and gelcoat are applied, layers of fiberglass and resin are laid-up onto the surface. The fiberglass used will typically be identical to that which will be used in the final product.

In the laying-up process, a layer of fiberglass mat is applied, and resin is applied over it. A special roller is then used to remove air bubbles. Air bubbles, if left in the curing resin, would significantly reduce the strength of the finished mold. The fiberglass spray lay-up process is also used to produce molds, and can provide good filling of corners and cavities where a glass mat or weave may prove to be too stiff.

Once the final layers of fiberglass are applied to the mold, the resin is allowed to set up and cure. Wedges are then driven between the plug and the mold in order to separate the two.

Advanced techniques such as resin transfer molding are also used.

1.How about the installation?

We provide installation instructions

A.The small product contains all the parts needed for installation. Just follow the instructions and connect them

B.We provide on-site installation service for large products. The product price includes personnel costs,Guests can only provide air tickets and accommodation

2.What about the after service?

A.Two years of after-sales service.

B .Provide lifelong technical service

3.can you provide personalized and customized product?

A.Of course, the customer provides the design and requirements. We will make a detailed production plan and confirm with the customer.

B.If the customer cannot provide the finished design, they can also provide the preliminary idea of the product or scene they want to do. We provide the reference opinion and the production plan to help the customer achieve the expectation.

We can provide customized service in mechanical structure, control mode, special effect, material texture, function.Such as stage props, activity props, performance special effects costumes, parade floats, scene special effects.

4.How long is the duration of the production?

A.Regular products, such as dinosaurs, animals, insects, Marine life, have A production cycle of 30 to 60 days,It’s different for depending on the amount.

B.Customized products need to consult with the salesman

5.why choose us?

A.we have our own production factory and 9 years of large project production experience

B.Stable and perfect company platform, strict quality and process management (OA & QCS)

C.Own r&d team (control system, mechanic, New material), and provide pre-sales technical support.

D.Provide product and scene plane and 3D design services

E. Multilingual service, barrier-free communication

F.24 hours Response to after-sales service

outdoor children playground equipment fiberglass theme park decoration fiberglass decoration sculptures playground decoration outdoor fiberglass cartoon lifelike animal model fiberglass animal decoration outdoor animal fiberglass cartoon fiberglass animal suppliers halloween theme park decoration outdoor animal statue waterproof outdoor fiberglass animal model

Cartoon fiberglass fiberglass sculpture

Fiberglass (American English), or fibreglass (Commonwealth English) is a common type of fiber-reinforced plastic using glass fiber. The fibers may be randomly arranged, flattened into a sheet (called a chopped strand mat), or woven into glass cloth. The plastic matrix may be a thermoset polymer matrix—most often based on thermosetting polymers such as epoxy, polyester resin, or vinyl ester resin—or a thermoplastic.

Cheaper and more flexible than carbon fiber, it is stronger than many metals by weight, is non-magnetic, non-conductive, transparent to electromagnetic radiation, can be molded into complex shapes, and is chemically inert under many circumstances. Applications include aircraft, boats, automobiles, bath tubs and enclosures, swimming pools, hot tubs, septic tanks, water tanks, roofing, pipes, cladding, orthopedic casts, surfboards, and external door skins.

Other common names for fiberglass are glass-reinforced plastic (GRP), glass-fiber reinforced plastic (GFRP) or GFK (from German: Glasfaserverst?rkter Kunststoff). Because glass fiber itself is sometimes referred to as "fiberglass", the composite is also called fiberglass-reinforced plastic (FRP). This article will adopt the convention that "fiberglass" refers to the complete fiber-reinforced composite material, rather than only to the glass fiber within it.

The fiberglass mold process begins with an object known as the plug or buck. This is an exact representation of the object to be made. The plug can be made from a variety of materials, usually certain types of foam.

After the plug has been formed, it is sprayed with a mold release agent. The release agent will allow the mold to be separated from the plug once it is finished. The mold release agent is a special wax, and/or PVA (Polyvinyl alcohol). Polyvinyl alcohol, however, is said to have negative effects on the final mold's surface finish.

Once the plug has its release agent applied, gelcoat is applied with a roller, brush or specially-designed spray gun. The gelcoat is pigmented resin, and gives the mold surface a harder, more durable finish.

Once the release agent and gelcoat are applied, layers of fiberglass and resin are laid-up onto the surface. The fiberglass used will typically be identical to that which will be used in the final product.

In the laying-up process, a layer of fiberglass mat is applied, and resin is applied over it. A special roller is then used to remove air bubbles. Air bubbles, if left in the curing resin, would significantly reduce the strength of the finished mold. The fiberglass spray lay-up process is also used to produce molds, and can provide good filling of corners and cavities where a glass mat or weave may prove to be too stiff.

Once the final layers of fiberglass are applied to the mold, the resin is allowed to set up and cure. Wedges are then driven between the plug and the mold in order to separate the two.

Advanced techniques such as resin transfer molding are also used.

+86-813-2104677

info@sanherobot.com

+86-13990010824

No.13 Huixin Road, Yantan Town, Yantan District, Zigong City, Sichuan Province, China